530 process pumps

Flow rates to 55 GPH (3.5 L/min) and pressures up to 100 psi. Precise 2200:1 speed control range.

Pumps - cased pumps

Call +1 800 282 8823

STA-PURE PCS pump tubing provides long term performance with repeatable accuracy, vital in pharmaceuticals and other high technology industries.

STA-PURE PCS has a unique composite construction of silicone in a PTFE lattice, giving it superior burst resistance up to 100 psi and 18 times longer life than silicone tubing. It produces virtually no spallation, is USP Class VI approved and is non-toxic, making it ideal for a wide range of biopharmaceutical applications.

Widely used for ultra-pure applications such as tangential flow filtration, ultra-filtration, live cell transfer, fermentation and bioreactor feed. Also used for aqueous tablet coating.

| Spallation | Very low |

| Certification and compliance | USP <87>, USP <88>, USP Class VI |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

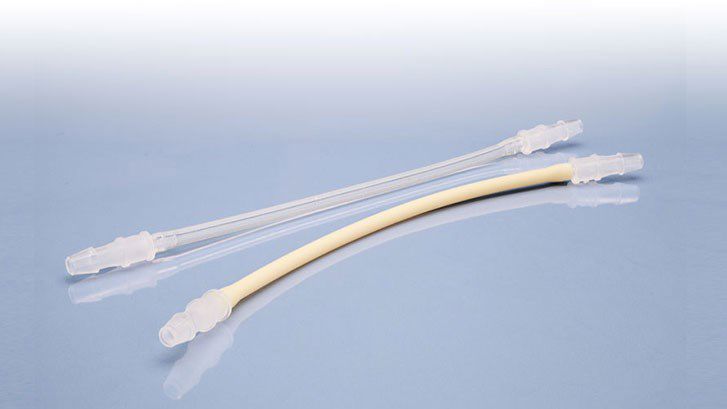

| GORE® STA-PURE Series PCS Tubing | GORE® STA-PURE Series PCS Elements | |

| Bore size | 1.6 - 25.4 mm | 1.6 - 25.4 mm |

| Bore size | 0.0625 - 1 in | 0.0625 - 1 in |

| Wall thickness | 1.6 - 4.8 mm | 2.4 - 4.8 mm |

| Wall thickness | 0.0625 - 0.1875 in | 0.0938 - 0.1875 in |

| Length | 305 - 660 mm | |

| Colour | Off-white | Off-white |

| Transparency | Opaque | Opaque |

| Spallation | Very low | Very low |

| Certification and compliance | USP <87>, USP <88>, USP Class VI | USP <87>, USP <88>, USP Class VI |

| Operating temperature range | -20 to 80 °C | -20 to 80 °C |

| Operating temperature range | -4 to 176 °F | -4 to 176 °F |

| Sterilisation methods | Autoclave, CIP, SIP | Autoclave, CIP, SIP |

| Tubing | ePTFE and platinum-cured silicone composite |

| Connector material | PVDF |

Request a validation pack for GORE® STA-PURE Series PCS tubing.

| STA-PURE PCS pump tubing sizes available | ||||||

|---|---|---|---|---|---|---|

| Bore | Wall | No | Element length | Part number | ||

| mm | inch | mm | inch | mm | ||

| 1.6 | 0.0625 | 1.6 | 0.0625 | 14 | 305 | 961.0016.016 |

| 3.2 | 0.1250 | 1.6 | 0.0625 | 16 | 305 | 961.0032.016 |

| 4.8 | 0.1875 | 1.6 | 0.0625 | 25 | 305 | 961.0048.016 |

| 6.4 | 0.2500 | 1.6 | 0.0625 | 17 | 305 | 961.0064.016 |

| 8.0 | 0.3125 | 1.6 | 0.0625 | 18 | 305 | 961.0080.016 |

| 1.6 | 0.0625 | 1.6 | 0.0625 | 14 | 355 | 961.0016.L16 |

| 3.2 | 0.1250 | 1.6 | 0.0625 | 16 | 355 | 961.0032.L16 |

| 4.8 | 0.1875 | 1.6 | 0.0625 | 25 | 355 | 961.0048.L16 |

| 6.4 | 0.2500 | 1.6 | 0.0625 | 17 | 355 | 961.0064.L16 |

| 8.0 | 0.3125 | 1.6 | 0.0625 | 18 | 355 | 961.0080.L16 |

| 1.6 | 0.0625 | 2.4 | 0.0938 | 119 | 355 | 961.0016.024 |

| 3.2 | 0.1250 | 2.4 | 0.0938 | 120 | 355 | 961.0032.024 |

| 4.8 | 0.1875 | 2.4 | 0.0938 | 15 | 355 | 961.0048.024 |

| 6.4 | 0.2500 | 2.4 | 0.0938 | 24 | 355 | 961.0064.024 |

| 8.0 | 0.3125 | 2.4 | 0.0938 | 121 | 355 | 961.0080.024 |

| 9.6 | 0.3750 | 2.4 | 0.0938 | 122 | 610 | 961.0096.024 |

| 6.4 | 0.2500 | 3.2 | 0.1250 | 26 | 610 | 961.0064.032 |

| 9.6 | 0.3750 | 3.2 | 0.1250 | 73 | 610 | 961.0096.032 |

| 12.7 | 0.5000 | 3.2 | 0.1250 | 82 | 610 | 961.0127.032 |

| 15.9 | 0.6250 | 3.2 | 0.1250 | 184 | 610 | 961.0159.032 |

| 9.6 | 0.3750 | 4.8 | 0.1875 | 193 | 610 | 961.0096.048 |

| 12.7 | 0.5000 | 4.8 | 0.1875 | 88 | 610 | 961.0127.048 |

| 15.9 | 0.6250 | 4.8 | 0.1875 | 189 | 610 | 961.0159.048 |

| 19.0 | 0.7500 | 4.8 | 0.1875 | 191 | 610 | 961.0190.048 |

| 25.4 | 1.0000 | 4.8 | 0.1875 | 92 | 610 | 961.0254.048 |

| STA-PURE PCS Double Segment Kynar Y-Element ordering codes | |||||

|---|---|---|---|---|---|

| Bore | Wall Thickness | Product codes | |||

| mm | inch | mm | inch | ||

| 1.6 | 0.0625 | 2.4 | 0.0938 | 961.E016.K24 | |

| 3.2 | 0.1250 | 2.4 | 0.0938 | 961.E032.K24 | |

| 4.8 | 0.1875 | 2.4 | 0.0938 | 961.E048.K24 | |

| 6.4 | 0.2500 | 2.4 | 0.0938 | 961.E064.K24 | |

| 8.0 | 0.3125 | 2.4 | 0.0938 | 961.E080.K24 | |

| 8.0 | 0.3125 | 4.0 | 0.1562 | 961.E080.K40 | |

| 12.0 | 0.4688 | 2.4 | 0.0938 | 961.E120.K40 | |

| 16.0 | 0.6250 | 2.4 | 0.0938 | 961.E160.K40 | - |

| STA-PURE PCS Loadsure Elements ordering codes | ||

|---|---|---|

| Product Name | Product codes | |

| STA-PURE PCS 520 LoadSure 3.2mm Bore Tri-Clamp Element | 961.0032.PFT | |

| STA-PURE PCS 520 LoadSure 6.4mm Bore Tri-Clamp Element | 961.0064.PFT | |

| STA-PURE PCS 520 LoadSure 9.6mm Bore Tri-Clamp Element | 961.0096.PFT | |

| STA-PURE PCS 620 LoadSure 12.0mm Bore Tri-Clamp Element | 961.0120.PFT | |

| STA-PURE PCS 620 LoadSure 17.0mm Bore Tri-Clamp Element | 961.0170.PFT | |

| STA-PURE PCS 720 LoadSure 12.7mm Bore Tri-Clamp Element | 961.0127.PFT | |

| STA-PURE PCS 720 LoadSure 15.9mm Bore Tri-Clamp Element | 961.0159.PFT | |

| STA-PURE PCS 720 LoadSure 19.0mm Bore Tri-Clamp Element | 961.0190.PFT | |

| STA-PURE PCS 720 LoadSure 25.4mm Bore Tri-Clamp Element | 961.0254.PFT | - |

Flow rates to 55 GPH (3.5 L/min) and pressures up to 100 psi. Precise 2200:1 speed control range.

Pumps - cased pumps

Flow rates to 4.76 GPM (18 L/min) and pressures up to 60 psi. Precise 2650:1 speed control range.

Pumps - cased pumps

Flow rates to 8.8 GPM (33 L/min) and pressures up to 30 psi. Precise 3600:1 speed control range.

Pumps - cased pumps

Thermoplastic tubing with long peristaltic life and low permeability. 23 ºF to 176 ºF (5 ºC to 80 ºC).

Tubing - peristaltic

Reinforced fluroelastomer tubing with extreme chemical resistance. -4 ºF to 176 ºF (-20 ºC to 80 ºC) to 60 psi.

Tubing - peristaltic

LoadSure elements allow pump tubing to be changed in under one minute, to achieve perfect tube alignment and tension.

Tubing - peristaltic

Thermoplastic elastomer tubing especially resistant to oxidizing agents. 23 ºF to 176 ºF (5 ºC to 80 ºC) to 100 psi.

Tubing - peristaltic

Platinum-cured silicone tubing with ultra smooth bore and excellent flow stability. -4 ºF to 176 ºF (-20 ºC to 80 ºC).

Tubing - peristaltic

High performance TPE tubing with exceptional life and accurate flow rates. Weldable and sealable for sterile connectivity.

Tubing - peristaltic

High quality silicone and chemical resistant TPE tubing. Over 50 bore/wall sizes and element lengths available.

Tubing - peristaltic

To order a product or ask a question